Brickmaking was a major employer in the village until 1990. The craft is known to go back to 7000BC when mud bricks were dried in the sun. It was the Romans that brought brick making to Britain in AD43 and modernised the process with mobile kilns. The bricks were shipped all over the empire for private and public buildings. When the Romans left the Brits went back to building houses out of timber and mud. It wasn’t until the 1400s that brick making returned.

Brickmaking was a major employer in the village until 1990. The craft is known to go back to 7000BC when mud bricks were dried in the sun. It was the Romans that brought brick making to Britain in AD43 and modernised the process with mobile kilns. The bricks were shipped all over the empire for private and public buildings. When the Romans left the Brits went back to building houses out of timber and mud. It wasn’t until the 1400s that brick making returned.

The Fletton brick industry (The generic name “Fletton” is given to bricks made from Lower Oxford Clay) which included the Eye works produced a revolutionary brickmaking process that was and still is the most “Green” bricks ever produced. The Lower Oxford Clay has a very high inbuilt fuel content that ignites itself and brings itself up to full burning temperature without the need for using coal, a unique feature of the “Fletton” brick industry of the Peterborough area that first started this new process off. This also makes the bricks cheaper to produce and was one of the main reasons for the growth of the brick industry in the Peterborough area. You can read more on the making of bricks (and the Dogsthorpe site) on the Dogsthorpe heritage site.

The clay was laid down over 150 million years ago in the Jurassic era. From the geology map to the right (click for larger version) its easy to see why excavating sand and gravel still continues to this day.

Until the early 1880’s it is thought many of the villages around Peterborough had their own small clay pits. These were not commercial but more likely a builder or brickmaker would have set up in whatever village would have needed his skills. One such pit was at Tanholt Farm where a pit was opened in 1835 to supply bricks for new farm buildings.

The first brickmakers are recorded as being in the village in 1855. The first commercial brickyards were just north of the Hodney Road allotments. The grass covered hill to the north of the village, visible from Green Road or either of the footbridges, was created from the surface soil and waste dug out from these works.

The first brickmakers are recorded as being in the village in 1855. The first commercial brickyards were just north of the Hodney Road allotments. The grass covered hill to the north of the village, visible from Green Road or either of the footbridges, was created from the surface soil and waste dug out from these works.

In May 1897 the Peterborough Advertiser reported “There is now ample scope for the labourer at Eye. Mr Hunting started his old brickyards, under the title of Messrs, Bailey and Hunting, (The Eye Fletton Works) and new plant is being put down. The digging for clay, also, at Eastwood has been up to the present quite a success; and if it continues it quite likely that very shortly another brickyard will be in full swing. One remarkable feature attached to the yard known as Mr Moore’s Brickyard (later the Northam works) is that there is a splendid surface of sand – reported to be some of the best in England – and the clay being of exceptional quality in brickmaking, contains qualities for producing some excellent cement.”

Of course, this work was not without its accidents. The Peterborough Standard of February 1903 reported “On Saturday, a young man named B. Nelson, whilst at work in a clay pit at Eye met with a nasty accident. A large piece of clay fell some 40 feet on to him. He was felled to the ground and remained unconscious. He was conveyed to Peterborough Infirmary where he rallied considerably towards evening”

It wasn’t only clay that was dug up. Local man Alfred Leeds made several finds in the local pits. In 1907, the Dogsthorpe works yielded the skulls of two prehistoric crocodiles and the Northam pit in Eye a small ichthyosaurus and part of a plesiosaurus. Northam was also particularly rich in the fossils of ancient shellfish. You can read more about the Leeds here.

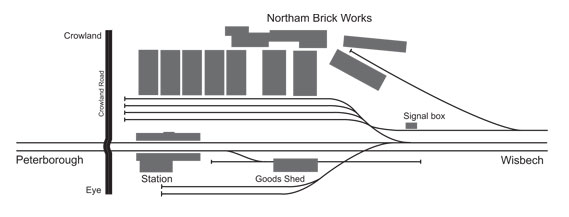

By 1900 there were two works in the village, the earlier Eye Fletton Brick Works and the newly built Northam Brick Works to the east of Crowland Road.

Eye Fletton Brick Works

For a relatively small works they seem to have had a colourful history. First worked in the 1850s the site was brought in March 1877 by Joseph Boam who lived in Stamford. His company, The Peterborough Patent Brick & Tile Co Ltd was registered on 29 October 1874. It was created with a share capital of £15,000 divided into 1,500 shares at £10 each. The company prospectus stated: “This company is formed for the purpose of purchasing certain freehold land in the parishes of Newborough and Eye, near Peterborough, where the clay has been proven to be of excellent quality and of great thickness”. The financial condition of the company was never healthy, the kilns were never as economical as hoped, the works only ran from spring to autumn and the machinery required continual maintenance which was expensive, some even had to be scrapped. The Peterborough Patent Brick & Tile Co Ltd went on to work the site until 1881, in the end it was voluntarily closed and the land returned to its original owner.

In a May 1897 the Peterborough Standard reported that Messrs, Bailey and Hunting were developing the site but this doesn’t seem to have lasted long as by January 15, 1898, the site was advertised as being up for auction at the Angel Hotel, Peterborough on the 29 January 1898 at four o’clock in the afternoon. The advertising quoted “The important and valuable brickyard, near the M. and G.N. Joint Railway, and fronting Green-road, Eye (half a mile from Eye Green Railway station), with dwelling-house thereon, farm premises.” A 14hp engine was listed as was a tramway from the pit, 2 kilns and 1/2 a million wire cut bricks.

The works were sold to Eye Fletton Brick Company, in 1902 they mortgaged the site to the Stamford, Spalding & Boston Banking Company who sold it the same year to J. W. Rowe, who owned the Dogsthorpe Star pit site from 1899 to 1914. For whatever reason the site seemed to never fully live up to its potential, the kilns were eventually demolished in 1913, and the site sold in 1919, it was then returned to agriculture.

Northam Brick Works

Eye farmer W. C. Moore leased 10-acre site (sand, gravel and clay pits) from the Bishop of Peterborough. He bought the land in 1897 and sold it, together with the bulk of the site, 62 acres, in the same year to the Northam Brick Company.

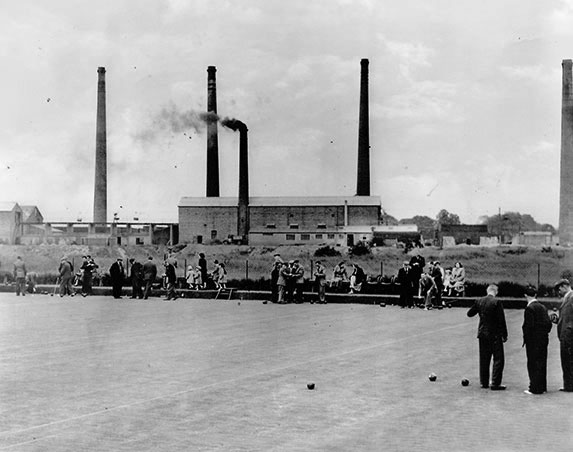

The first two kilns were built in 1897, one more was added in 1898 and two more in 1899. The chimneys were around 90m high, the nearby Midland and Great Northern Railway would have been a major stimulus to the development of the works as it was the cheapest way to transport bricks at the time. The sidings would have been a busy place with bricks being loaded into trucks by hand – this would have been before the days of palletisation and forklifts. Until road haulage took over the majority of the bricks were transported by railway.

In 1899 a local newspaper was reporting that 340,000 bricks from the Northam Works had been used in the construction of Westminster Cathedral in London. Stilwells Fletton Brick Company who were based in Woodston in Peterborough were commissioned to provide the bricks (Fletton wire-cut) for much of the structural work in the cathedral. They weren’t able to keep up with demand so purchased additional bricks from a number of local yards including the Northam yard in Eye.

The cathedral was designed in an early Christian Byzantine style inspired by St Mark’s in Venice and the Hagia Sophia in Constantinople which is why a lot of bricks were needed. In total some ten million bricks were from the Peterborough area were used for construction, amounting to about 80 per cent of the total number of bricks in the building. There are thought to have been around 12.5 million hand-made bricks used in the construction which was completed in 1903.

In September 1899 a trip to Great Yarmouth was organised by the Northam Brick Company for their employees. Employees caught the train at Eye Green station with a 100 relatives in tow. It was reported that it was a fine day and a full train with plenty of excitement.

Ib 1902 the company became a member of the Institute of Clayworkers.

In 1906 the British Clayworker: Volume 14 reported that the yard had won a large contract: “The Northam Brick Company has secured a contract to supply several million bricks for the erection of a hospital at Gibraltar, and the first shipload was dispatched last month. The bricks are sent a train-load at a time to Lynn and shipped from there.”

Minor additions of land were made in 1925 and 1927. On 23 September 1924, the site was acquired by the London Brick Company. Three more kilns were added in 1926 and in May 1927 there was news that the owners were asking the council permission to build a ropeway from Dogsthorpe to the Northam Brickyards. It was eventually given in June the same year. The ropeway was eventually built-in in 1928.

The Aerial Ropeway

Many who lived in Eye until the 1980s will remember the screeching and clanking of the ropeway as the buckets made their way to and from the Northam works along the north side of the village.

The ropeway was built so the kilns could keep operating. Clay was carried a mile on buckets from Dogsthorpe to Eye. The buckets were suspended from a hanger, which they are held fast by a combination of gravity and friction between the rope and a set of clips. As a bucket approached the station, the wheels engaged with a rising rail to lift the clips off the rope. The bucket was then free to run along this rail, which allowed it to be manually controlled during the loading and unloading processes.

Below is Claughton aerial ropeway, Lancashire owned by Hanson, it was the last working ropeway in the UK. Built just four years before the one in Eye it is of a very similar design.

The brickyards were in continuous for most of their life but during the great depression of 1929 over three million people were unemployed across the country and for a period of about two years the brickworks were closed. On the 16th March 1933, a parade of brick workers took place in the village in thanks for works re-opening.

During World War I and II when the brick industry was virtually idle, the kilns were used for the storage of explosives and ammunition. Due to this, they became a target for German Aircraft. In fact during the building of the Eye bypass an unexploded bomb was found and the bomb squad where called. Despite being idle during the war, 50’s and 60’s post-war London was a big market for bricks.

Closure

Closure

The lose of the railway in the 1960’s must of been a major disruption to the works. Although road haulage was a growing industry, trains were still an economical way of moving bricks.

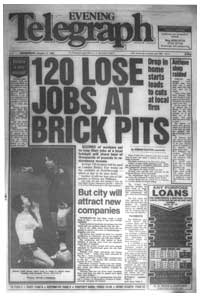

The biggest blow came in 1990 when London Brick announced the closure of the Eye (and Dogsthorpe) works. The country was in the midst of a recession and house building had ground to a standstill. The works employed 120 people and the entire workforce was to be laid off. The site was the smallest of the London Brick sites and clay at the Dogsthorpe pit was running low.

Some had worked the pits for over 30 years. The redundancy packages were around 200 per cent above the legal minimum which lessened the pain for many of the workers.

Reported at the time: “They have been going to close the site for the last 15 years” said union shop steward Mick Snart. “I don’t think anyone was really surprised when they told us about it”.

Many of the workers were reported to be in a jovial mood as they left the factory and said the company had treated them fairly well over redundancy and severance payments.

The chimneys at Eye were demolished on the 22 December 1990 and the rest of the works slightly later.

Today

In 1997 ownership of Dogsthorpe Star Pit was transferred to the Wildlife Trust, the Northam pit is also a nature reserve. The site of the Northam works in Eye is soon to be a housing estate and the south pit at Dogsthorpe is currently used for landfill although its due to filled within the next 10 years.

Bricks

Here are a selection of bricks from the Northam site, the number signifies where the bricks were made. 19 was the Northam Works.

Notes

Peterborough Northern Star Football Club was originally formed as a village side from the two brickyards, Northam in Eye and the Star brickworks in Dogsthorpe in the early 1900s before being renamed Eye United in the early 1950s. The club was highly successful and moved into Peterborough in 2003. It was renamed Peterborough Northern Star in 2005, after its original name.

On the changing of parish boundaries in 2004 the Dogsthorpe site became part of Eye Parish.

London Brick was acquired by Hanson in 1984.

Price of Common Fletton bricks from 1896 (per thousand)

- 1896 – £1.10

- 1908 – 42p

- 1975 – £52

- 1982 – £55

- 1996 – £150

- 2013 – £400

Reference

The structure of the British Industry 1958

Eye Life by Philip J. Randall

Clay That Burns by Richard Hillier

Wikipedia – The London Brick Company

Further information

Brick Types

Could you please advise if they made a yellow brick, as I have unearthed a quantity of yellow bricks in Bourne with the stamping in the frog “Northam Eye Green”

I would be very pleased if you were to contact me.

Yellow bricks seem to be the common brick made at the Eye green works . I’ve got 60 bricks with different names its interesting to see what was made where .

Can you tell me when the Claydon Red Multi was first produces?

Would anybody have information about the London Brick Company in the mid 1920s? Did they launch a nationwide recruitment drive?

My query arises from family history research in which a family member aged 16, moved seemingly at random from Yorkshire to work in the Brick works at Peterborough.

This was done without any other family members being in the area. I am just curious as to why a young lad who had probably never ventured far, should in 1926 aged 16 travel over a hundred miles and start working in a brick works in Peterborough.

This person stayed there 15 months or so, then went back to Yorkshire for a time, before returning again a few years later, again to the brick works.

Yes they did have a recruitment drive after the war. For more information please contact sasmc2000@yahoo.co.uk

The Bailey, was William Morton Bailey, Auctioneer and Hay Merchant, Landlord of the Black Swan, Midgate, Managing Director of the Peterborough Omnibus and Carriage Company Ltd and my Great Grandfather

should like to know the correct spelling for a disused brick pit filled with water- sounds like knothole, which of course has another meaning in relation to wood. Have heard the term marlhole used in the West Midlands.

My house was built in 1923/24 and 2 sides of my house has “Pboro United stamped in the frog these are common bricks, are they unusual or fairly common?